YSD power supply QUALITY CONTROL SYSTEM

2020-05-12 01:31:24

YSD power supply QUALITY CONTROL SYSTEM

As we know , product quality effect the market and reputation.YSD is very concern about it ,as this is the important point for us to catch the market and keep good reputation with all of our customers

YSD dust-free workshop to protect the working environment

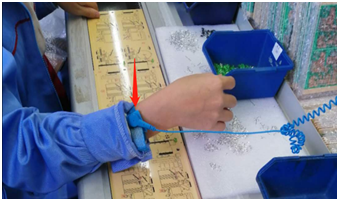

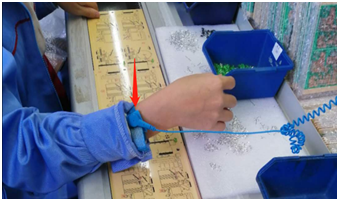

wear static ring to make sure working security

Plug in part testing

Plug in part testing

Process wave soldering and QC double check

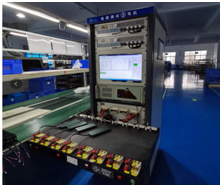

1stProduct performance testing by ATE machine

all tested automatic by computer to avoid human error

Quality inspection area

Glue filling machine

Using for IP67 products , all material is PU glue

100% High voltage testing

All products need to pass the high voltage testing ,and then use the ATE to process teh performance and data testing again .

To make sure all can work well during the warranty

2nd ATE testing

2nd ATE testing

Laser label

All products need to process 3 times of ATE testing ,1 high voltage testing ,4-8 hours aging testing ,then can start packing

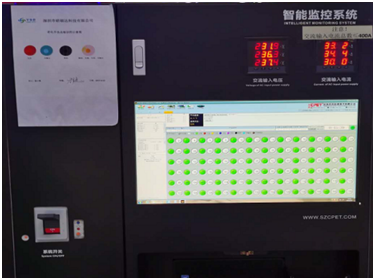

Aging test

We use the best,advanced aging testing machine,you can see the real-time monitoring data and aging hour on the computer

The aging testing machine can process Cyclic aging and cyclic impact testing under input voltage of 110V ,220V ,305V according to customer’s request

Can process the standard aging testing for Global voltage ,High voltage and Low voltage products

Aging testing time

IP20 -- 3hours

IP67 -- 4hours

We can arrange aging testing time to 8hours according to customers’ request

Automatic packing machine